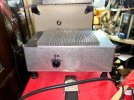

It's really good to see these attenuators that people have made, I would like to try one myself. I've seen that there is a thread about building them, but it's 175 pages!

I've seen a parts list for version M of the JohnH attenuator on page 13, but rather than reading the rest of the 175 pages could someone please guide me to the right page. I want to build a 16 Ohm one for a 30W Valvetone amp, which is Australian, and the M model @JohnH describes sounds good.

I've seen a parts list for version M of the JohnH attenuator on page 13, but rather than reading the rest of the 175 pages could someone please guide me to the right page. I want to build a 16 Ohm one for a 30W Valvetone amp, which is Australian, and the M model @JohnH describes sounds good.