bordonbert

Member

- Joined

- Jan 24, 2015

- Messages

- 59

- Reaction score

- 15

Hi guys. I am in the middle of modding my 2210 to do a couple of things.

I'm removing the revolting IC CA3046 transistor array that Marshall had to use to do the channel switching. Honestly, BJTs are the last thing that we should be using to ground out AC signals. I have a tiny 3V relay board design with MOSFET control which will do the job properly and it sits in the original IC holes. I have now socketed the IC slot so it can take either the original CA3046 chip for a future owner who may prefer to have it as original action or my own PCB which sits on a couple of 7 pin SIL connectors tight in the socket. It only needs a couple of other simple mods on the amp PCB, remove one leg of a diode and short out a few components with wire links. All of these are easily reversible which is something I try to keep to.

I am also converting the red Drive channel LED indicator to a green/red type which just looks so much nicer I think. No, it isn't necessary but it's an easy job and it neatly fits in with the channel selector mod as the LED transistor is controlled from the same source. It only needs adding a resistor and diode to the amp PCB on existing components and swapping out the BC184 for a general purpose MOSFET with the same footprint.

I'm also going to fit a high voltage transistor buffer between the output of the preamp channels and the Master Volume. The volume control in the 2210 is appalling and it's famous for it, it's virtually 1 bit digital, kind of just a switch! I have a good idea what the issue is and a simple clean buffer will allow the MV to work as it should, a properly set up pot and not just a variable resistor as it is originally!

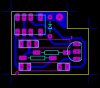

Anyway, as there was a bit of identification and chasing through to be done on the PCB I thought I'd spend a bit of time working through the layout as I hadn't been able to find it online anywhere. I'm posting where I am with it now in the hope that someone will be able to check it out and critique it for errors.

One thing I have found is that the Clean channel selection setup is not the same as the standard online schematic for the 2210 shows. Channel selection is normally done by simply shorting the signal to ground at either the input of the Clean channel at its Volume control wiper, or at the input and output of the hated diode clipping stage at its Gain and Volume wipers. At least "shorting to ground" is the intention but a BJT behind a cap with no DC on its collector is going to do an appalling job of that, as we know! My own 2210 is a '89 version so is pretty late in the run and the Clean channel switching is not performed quite as standard. C40 on the schematic is missing. It's actually labelled C38 on the PCB. The Clean channel is muted by handling the wiper of the Bass control instead via a 220nF cap attached under the board between the IC and the pot. You can easily see it in the picture in the top left with the yellow sleeved legs. It could be someone's previous mod of course but this sort of thing is not unusual in the lifetime of a product run so I wondered if anyone knows whether this is a genuine Marshall production line mod.

If there is any interest and I'm not dragging up old news which is long dead and gone I will post details of the mods once they are done. I can share the PCB, (1"x1" single sided for diyers), and details of how to improve the control and remove that hated channel bleed. It really is down to the nasty way the Master Volume and Channel selection have been implemented and not due to crosstalk or anything as complex as that.

I'm removing the revolting IC CA3046 transistor array that Marshall had to use to do the channel switching. Honestly, BJTs are the last thing that we should be using to ground out AC signals. I have a tiny 3V relay board design with MOSFET control which will do the job properly and it sits in the original IC holes. I have now socketed the IC slot so it can take either the original CA3046 chip for a future owner who may prefer to have it as original action or my own PCB which sits on a couple of 7 pin SIL connectors tight in the socket. It only needs a couple of other simple mods on the amp PCB, remove one leg of a diode and short out a few components with wire links. All of these are easily reversible which is something I try to keep to.

I am also converting the red Drive channel LED indicator to a green/red type which just looks so much nicer I think. No, it isn't necessary but it's an easy job and it neatly fits in with the channel selector mod as the LED transistor is controlled from the same source. It only needs adding a resistor and diode to the amp PCB on existing components and swapping out the BC184 for a general purpose MOSFET with the same footprint.

I'm also going to fit a high voltage transistor buffer between the output of the preamp channels and the Master Volume. The volume control in the 2210 is appalling and it's famous for it, it's virtually 1 bit digital, kind of just a switch! I have a good idea what the issue is and a simple clean buffer will allow the MV to work as it should, a properly set up pot and not just a variable resistor as it is originally!

Anyway, as there was a bit of identification and chasing through to be done on the PCB I thought I'd spend a bit of time working through the layout as I hadn't been able to find it online anywhere. I'm posting where I am with it now in the hope that someone will be able to check it out and critique it for errors.

One thing I have found is that the Clean channel selection setup is not the same as the standard online schematic for the 2210 shows. Channel selection is normally done by simply shorting the signal to ground at either the input of the Clean channel at its Volume control wiper, or at the input and output of the hated diode clipping stage at its Gain and Volume wipers. At least "shorting to ground" is the intention but a BJT behind a cap with no DC on its collector is going to do an appalling job of that, as we know! My own 2210 is a '89 version so is pretty late in the run and the Clean channel switching is not performed quite as standard. C40 on the schematic is missing. It's actually labelled C38 on the PCB. The Clean channel is muted by handling the wiper of the Bass control instead via a 220nF cap attached under the board between the IC and the pot. You can easily see it in the picture in the top left with the yellow sleeved legs. It could be someone's previous mod of course but this sort of thing is not unusual in the lifetime of a product run so I wondered if anyone knows whether this is a genuine Marshall production line mod.

If there is any interest and I'm not dragging up old news which is long dead and gone I will post details of the mods once they are done. I can share the PCB, (1"x1" single sided for diyers), and details of how to improve the control and remove that hated channel bleed. It really is down to the nasty way the Master Volume and Channel selection have been implemented and not due to crosstalk or anything as complex as that.

Attachments

Last edited:

The schematic shows D4 connecting to IC1 pin 9 and D5 connecting to pin 6 (not actually labelled on the diagram). Though I have said it is an error, this is actually correct!

The schematic shows D4 connecting to IC1 pin 9 and D5 connecting to pin 6 (not actually labelled on the diagram). Though I have said it is an error, this is actually correct!